Product Identification / Warranty / Service Policy

~ LLC had changed our PRODUCT CODES for extending the coverage ~

1. For laser cutting machine such as LCM / LCD / LCR / LCG (Group A) and LCW / LCU / LCK / LCI (Group B), LLC does not continue to offer them under OLD MODEL NAME. What will we do next ?

2. For laser engraving machine such as LEW / LEE /LEN (Group C), E96 / E64 (Group D) and LEQ ,LLC does not continue to offer them under OLD MODEL NAME. What will we do next ?

We aimed at Laser Welding Machines with below listed configurations.

You are welcome to contact our sales people for discussing your specific needs.

Laser Welding Small Parts, QCW Laser -1

Laser Welding Small Parts, QCW Laser -2

Laser Welding Small Parts, QCW Laser -3

Laser Welding Small Parts, QCW Laser -4

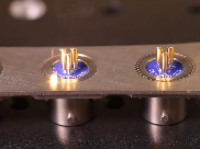

Laser Welding WorkCell -1

Laser Welding WorkCell -2

Ball screw lubrication is important for its life and performance. The best lubrication is light oil applied directly into the ball nut at various locations along the length of the screw. Light spindle oil or light way lube is recommended. Grease can also be used for ball screw lubrication because it doesn’t entail complicated delivery methods, and it requires less frequent re-lubrication intervals.

a.Open MDI window: Viewà Show MDI Window(M)

.png)

b.Key in”$***” then press ENTERà Reboot after a few seconds

This command clears all data of the controller

c.Key in “$” then press ENTER

This command is to load data into the controller from flash

DIP SWITCH 1 the same as $*** command

DIP SWITCH 7 the same as $ command

For updating EZLASER Firmware, please scan following QR code and visit the web page to answer all of the questionnaires for gettting quicker response from our technical support team.